Permanent Magnets & Magnetic Separator

Permanent Magnets

Suspended permanent magnet with manual cleaning, the simplest and cheapest equipment for the separation of ferromagnetic particles from materials transported on a belt conveyor. This permanent magnetic separator is suitable for materials with lower content of magnetic metal particles (if the cleaning is not required more often than once a work shift).

How the suspension magnet cleaned?

The magnetic plate is suspended above the belt conveyor and the magnetic impurities are captured at the bottom of the magnetic plate (usually fitted with strong permanent ferrite magnets, however on client’s requirement is possible to use extremely strong neodymium NdFeB magnets). The ferrous particles accumulated on the surface of the magnetic plate are removed manually. If the material contains too many ferromagnetic particles, the magnetic plate is swiftly clogged with ferrous particles. In this case we recommend that the clients opt for our overband magnetic separator with automatic cleaning.

Easy cleaning suspended magnet

Magnetic plate can be equipped (at extra charge) with a cleaning stripper tray for simple removal of the trapped magnetic particles. On the bottom of the cleaning stripper tray (that protects the magnetic core steel plate) there are longitudinal steel slats that prevent the captured ferromagnetic particles from jumping onto the magnetic core steel plate during the cleaning (when the cleaning stripper tray is being drawn out) and also ensure uniform distribution of the trapped ferrous material on the stripper tray surface.

Dimensions of the permanent suspension magnet

The magnetic plate with manual cleaning can be made in any size according to customer’s needs.

Suspended magnet on a rail construction

Manual cleaning permanent magnetic separator on a special rail construction is a sophisticated version of the suspended magnet. Thanks to the rail construction it is possible to move the magnetic plate aside and carry out the cleaning or maintenance in a very easy and safe way even without stoppage of the conveyor belt.

Combination of a suspension magnet with a magnetic pulley

In order to achieve the most efficient iron tramp separation in case of a high layer of the transported material, we recommend to combine the use of the magnetic plate with our magnetic pulley that can separate the ferromagnetic particles also from lower layers of the transported material.

Magnetic Separator

Weartech Solutions Magnetic Separator overhead magnet is a non-electric suspended separator, suspended over a conveyor or head pulley to remove ferrous metals.

Design Features

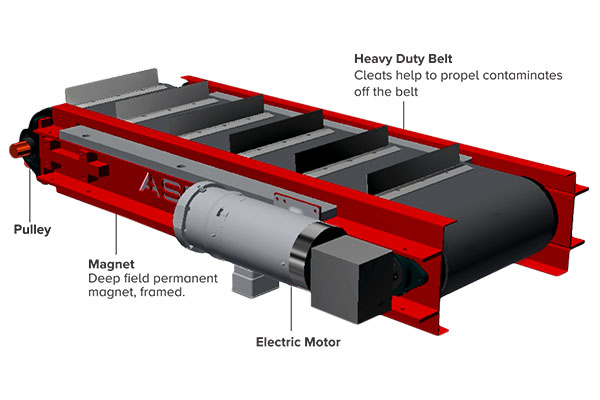

- Continuous Cleaning – Ensure zero downtime during production for cleaning and also guarantee contaminants are safely removed from the product flow.

- Cleated Belt – Moves the attracted ferrous material from nonmagnetic materials, which is moved by a separator belt to a collection bin or chute.

- Innovative Design – Allows for excellent and calculated product stream coverage for optimum separation and cleaning efficiency.

- Custom Belt Size Available – Weartech Solutions can customize the size of the belt to fit any width.

- Belt Option – High Temp. Belts, Rubber Belts, Polyurethane Belts, Armor Clad Belts etc.

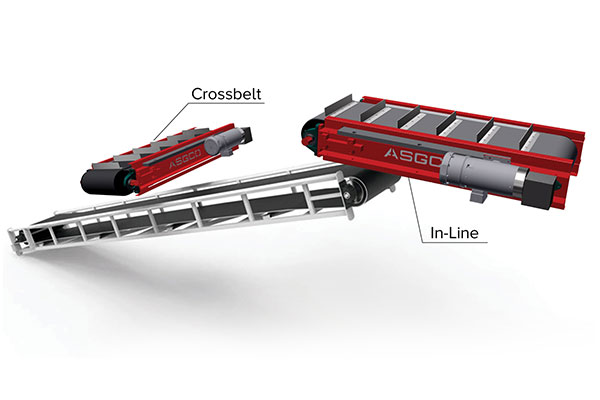

- Crossover or In – Line arrangement Available.

High-Volume Separator

Weartech Solutions permanent overhead self-cleaning magnet separator is suspended over a conveyor or head pulley to remove ferrous metals. Metal is attracted by the self cleaning model and is automatically and continuously removed from the magnet face by a belt that travels around the body of the magnet. No external power source is required for the magnet. Weartech Solutions Magnetic Separators may also be placed at end incline to provide customised Magnetic Separator. Custom Magnetic Separators can be made on request, please send us your technical data and application, required for our engineers to provide.

- Protecting Equipment

- Ensuring Product Purity

- Recovering Materials

Metal Detector

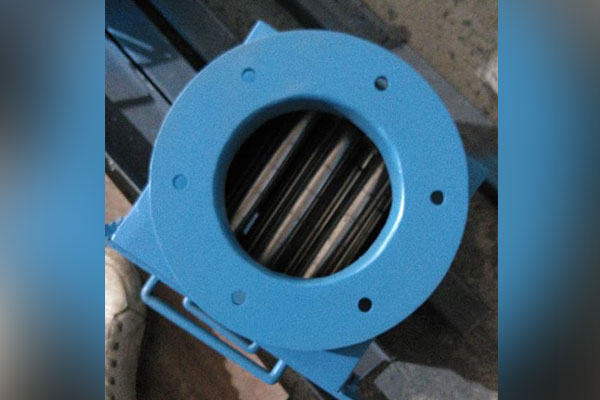

Metal Detector is used to detect metal parts on a moving Conveyor Belt. The Metal detector Initially gives audible and visual alarm when a suspect metal object when passes over its sensor coil. This give relay to Conveyor drive motor to STOP . Once the metal foreign particles are removed , it is give a RE START command.

Application in which Metal Detector is useful:

1) Roller Press feed belt

2) Vertical Roller mill feed belt

3) Crusher Application

Components that are supplied are:

1) Conveyor Metal Detector

2) Sensor Coil & Control panel

3) Siren/ Hooter (Optional)

4) Cable and Connectors

Technical Details

1) Alarm Mode: Sound

2) Brand: Weartech Solutions

3) Usage: Industrial

4) Size : Ranges from 800 mm Belt width to 2200 mm Belt width.

5) Material: Waterproof

6) Finishing Type: Smooth

7) Features: Automatically Detects metal objects such as Iron, Nut bolts, Casted Metal (Any kind of Ferrous or Non Ferrous particle).