En-masse & Screw Conveyors

Introduction

En-masse

Weartech Solutions has been one of the pioneers in India to manufacture and supply Drag Chain conveyor/En-mass Chain conveyor/Spillage Chain conv (Long length)/Scrapper chain conv (Wide).

Slow moving chains in these conveyors influence the material to move gently through a closed duct in a horizontal or even in steeply inclined profiles. These can handle virtually any type of bulk material in an environmentally safe way due to its dust-tight and spill proof, totally enclosed construction. These conveyors are heavy duty and made of rugged construction. The conveying profile can vary from horizontal to near vertical direction. The material is conveyed with ‘En-masse’ effect or ‘Drag’ effect. En-Masse conveyors provide a cost advantage due to their low power consumption, compact size & low maintenance requirements.

Weartech Solutions uses its own brand of drop forged chains. But conveyors with roller pin chains or round link chains can also be designed if the client requirement demands so. The company has previously supplied Chain conveyers from 2 to 350 TPH with casing width varying from 200 mm to 1250 mm and length up to 155 meters.

Chain elevators are an excellent alternative for pneumatic systems where moisture percentage in the material to be handled is upto 30 % and where pneumatic systems fail. Weartech Solutions can provide a combination system which includes mechanical conveying using chain conveyors followed by pneumatic conveying to achieve long distance transfer of bulk material.

Technical Details

- Weartech Solutions Chain conveyors are custom designed to suit the bulk material to be handled. For given operating parameter like speed, Bulk density, capacity, length, inclination, Temperature etc. For a chain conveyor, it is the material properties which decide whether the conveying will be with ‘En-masse’ effect or ‘Drag’ effect. Weartech Solutions’s vast experience in this field ensures that the conveyor is designed to operate at optimum efficiency by proper selection of speed, type of chain & flight etc.

- The conveyors are designed with single or multiple numbers of inlet and discharge openings provided at the required locations along the conveyor path.

- The conveyors are manufactured according to applications using Carbon Steel, Stainless Steel or other such material with various types of lining.

- Weartech Solutions chains are made of alloy steel drop forgings. They are machined and heat treated to achieve desired strength and hard outer surface to withstand wear due to abrasion.

- Sprockets suitable for the forged chains are also manufactured by Weartech Solutions in Carbon Steel and Alloy Carbon Steel which are case hardened for longer life.

- Flights of different shapes and construction are welded or bolted to the chain links as per following drawings.

- Weartech Solutions chain conveyor can handle temperature up to 750 Deg C

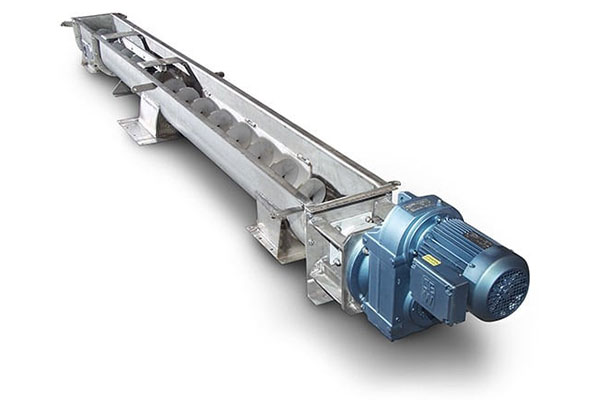

Screw Conveyor

Screw conveyors are used to convey the material continuously with the help of a rotating helical screw blade (known as flights) by shear and tumbling effect inside a U shaped trough or a round tube. They are generally used for handling fines of coal, crushed material, powders, cement, chemicals etc.

The periphery of leading side of the helix is provided with hard face welding for handling abrasive material. We offer screw conveyors in standard and customized solution to address varied requirements.

Weartech Solutions also offers water cooled screw conveyor for handling and cooling material with very high temperature. We have supplied such conveyors for temperatures upto 900ºC.

Screw conveyors have the following applications:

- Cement Industry: Cement, Dry & Damp Fly Ash, Coal Mill Dust, Clinker Dust, ESP Dust, Sepax Dust, Raw Mill / Kiln Cooler Dust.

- Food Industry : Soya bean cake and seeds, De-oiled cakes, Solvent extraction System for Edible oil industry, Sugar (Finished Goods)

- Chemical Industry: Stable Bleaching Powder, Soda Ash, Pue PTA, Hydrated Lime for Paper Industry, Polyfibre Industry and Bleaching Powder Industry, Carcinogen.

- Power Industry: Alternative Fuel ( Rice Husk /Cow Dung)

- Paint Industry: Sludge

- Steel Industry: Sinter Dust, Iron Oxide Dust, Burnt Lime, Calcined Lime, Pellet Dust

- Paper Industry: Burnt Lime

Technical Details

- Standard screw conveyors are made out of carbon steel or stainless steel depending on the operating conditions.

- Sizing of screw conveyor and pitch of flight is determined with the reference to CEMA standards.

- Intermediate hanger bearings are provided for long conveyors for the screw to maintain allowable sag in the rotating member.

- Proper selection of angular speed for the screw conveyor is critical in order to avoid wobbling effect during operation.

- The tough filling factor is selected according to nature of material and also with reference to CEMA standard with typically value of around 30%; however, the drive power rating is calculated based on 100% filling factor.

- For high temperature applications, a jacketed trough and box type flights are provided with circulating cooling water through, shaft & box flights. The quantity of cooling water depends on the properties & temperature of conveying material. If required, hollow flight configuration with cooling water circulated through their internal cavity can be provided to reduce temperature of the conveyed material.